contact

+32 9 228 10 81

info@nelen-delbeke.be

address

Industriezone 17

9770 Kruisem – Belgium

+32 9 228 10 81

info@nelen-delbeke.be

Industriezone 17

9770 Kruisem – Belgium

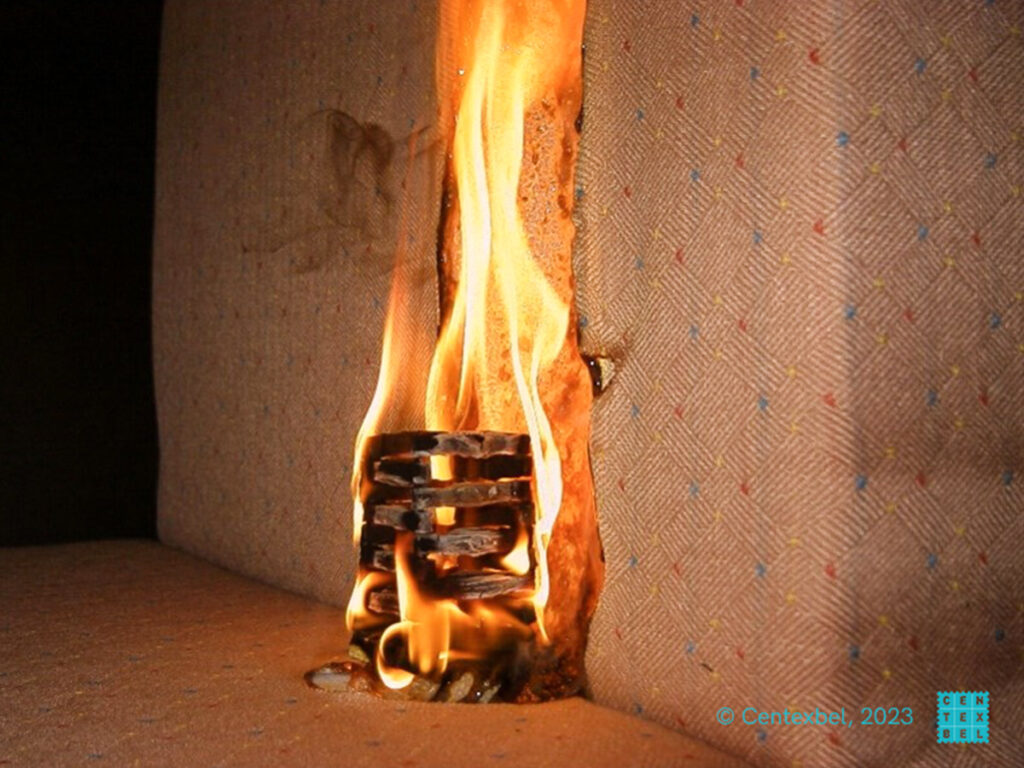

In the NF P 92-504 test, the specimen is placed vertically. A small flame is applied 10 times during 5 s. Afterflame times > 2 s and burning droplets are the most important criteria in this test. In the NF P 92-505 test, the specimen is placed horizontally on a grid beneath a radiator. Burning droplets that ignite the cotton wool below the specimen lead to an M4-classification.

Nelen & Delbeke is a 4th generation family owned weaving mill committed to providing its customers with a broad range of exceptional products that are distinguished by their excellent design. This thanks to a complete updated and hightech loom park.

+32 9 228 10 81

info@nelen-delbeke.be

Industriezone 17 – 9770

Kruisem – Belgium